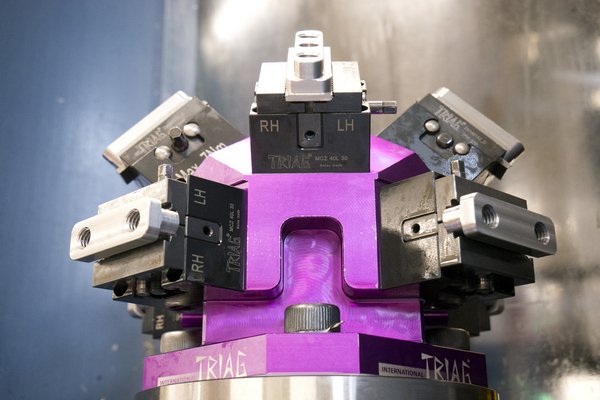

Workholding modules for dedicated fixtures

The microCLAMP system includes more than 50 workholding modules. The high workholding density (starting from only 15 mm between workpieces) is achieved by using the back side of the clamping modules as a stop surface for the next workpiece.