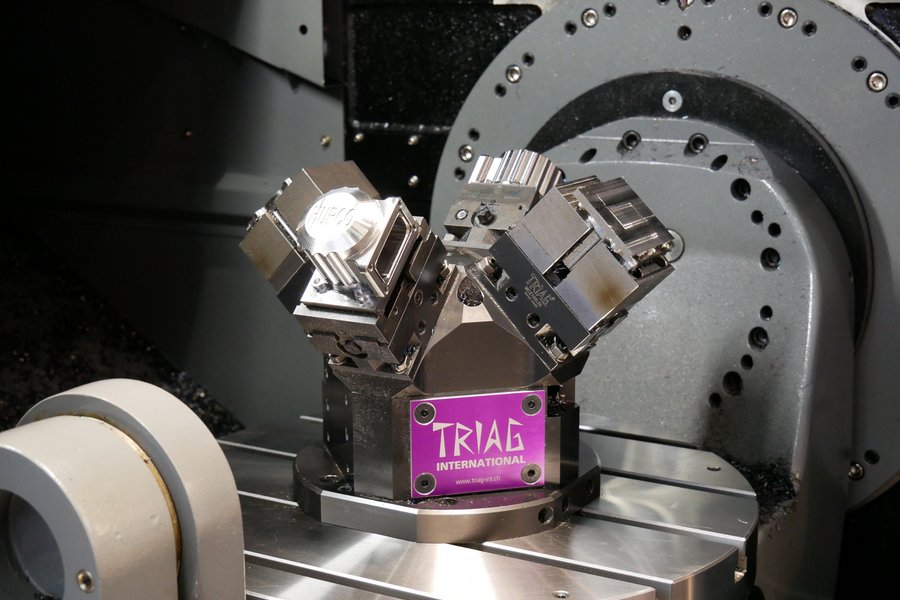

Tailored to machine and workpiece

Our self-centring vises are available in various sizes and designs and can be selected based on the machine and workpiece. In addition to compatibility with our rail system powerCLAMP and our zero-point system oppSYSTEM, versions for hole patterns are also available.