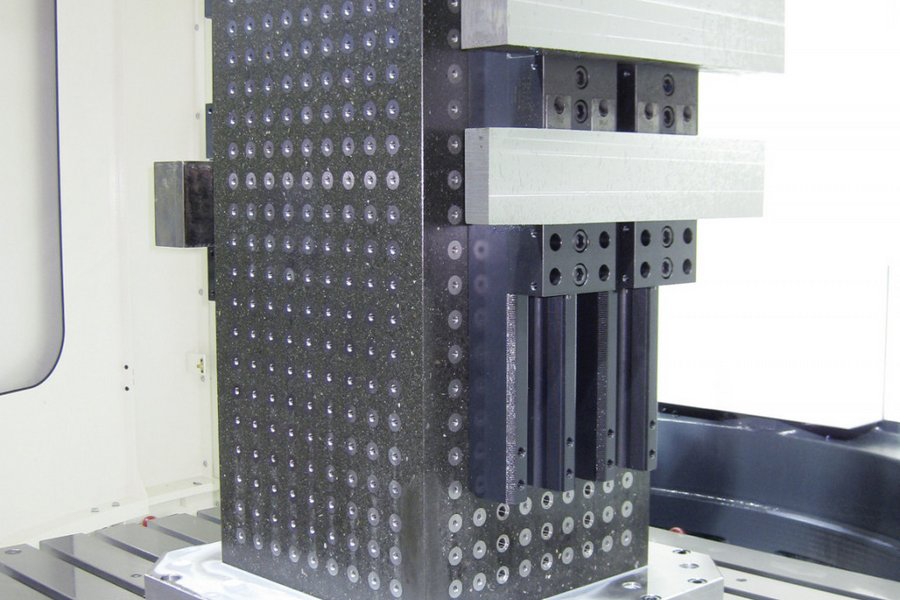

Stable, robust and precise

The high clamping force of this system enables its use for heavy-duty machining. With stable, robust modules, even large plates and blocks weighing up to several thousand kilograms can be clamped on the base rails.

Workholding system for heavy duty machining

aptoCLAMP is one of the strongest workholding systems, designed for the machining of very large and heavy workpieces, weighing up to several thousand kilograms.

In our aptoCLAMP brochure, you'll find the complete selection of clamping modules, their technical specifications, and some application examples.

If you have any questions or are ready to optimize your mechanical production facility, feel free to contact us directly.

The high clamping force of this system enables its use for heavy-duty machining. With stable, robust modules, even large plates and blocks weighing up to several thousand kilograms can be clamped on the base rails.

Maximum clamping force: 7,000 daN

Positioning steps: 2 mm

Clamping stroke: 5 mm

Base rail length: 400 – 800 mm

Mounting grid of base rails: 40, 50, and 100 mm

Base rail heights: 70 mm

Thanks to a 2-mm step on the base rail, clamping and stop modules can be quickly and precisely positioned. The rail allows for backlash-free pairing, while clamping forces are robustly absorbed and securely anchored by an expanding wedge. Additional modules can simply be installed between the existing clamping units.

The aptoCLAMP system includes 20 modular pull down and linear clamping modules. Each module can be used as a stop module (except 5-axis modules), enabling high workholding density and multiple workholding.

To position the clamping modules, the aptoCLAMP system uses a 2-mm serration. In addition to a crosswise serration, there is an additional lengthwise serration to lock the anchor system, providing very high stability and rigidity even during heavy-duty machining.

The clamping modules rest on the precisely ground contact surface, ensuring that the clamping module remains extremely force-locked and precisely fixed to the base rail. Nevertheless, released clamping modules can be freely moved along the base rail. The modules can be easily lifted up for replacement or installed from the top without the need to retract them from or into the rail.

Explore the complete selection of modules, their sizes, and some application examples in our aptoCLAMP brochure, or contact us directly to unlock the full potential of your machining process.