The best of old and new

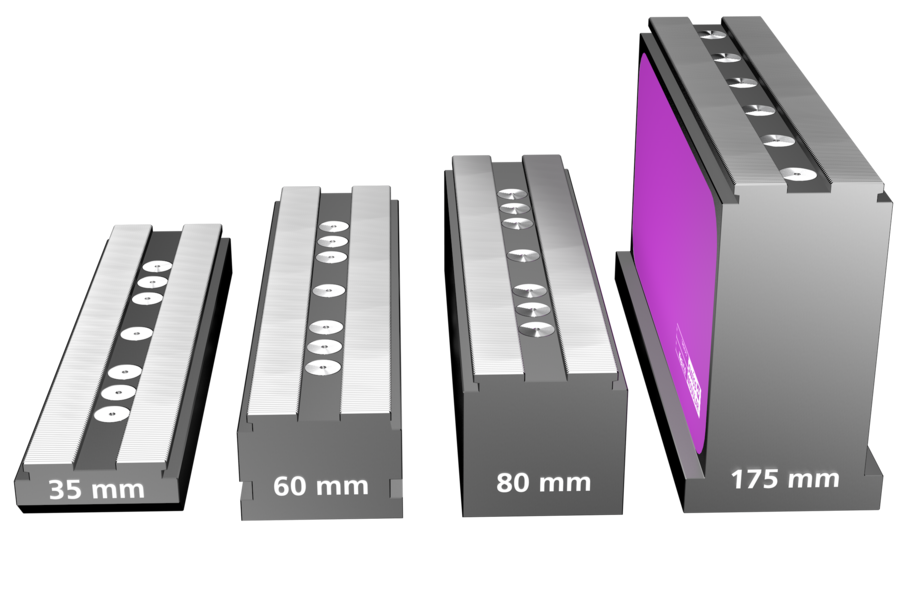

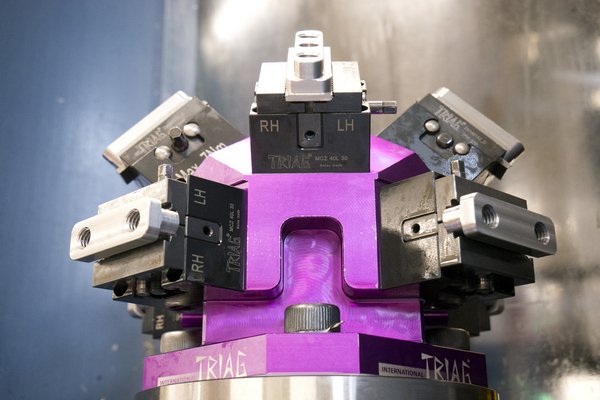

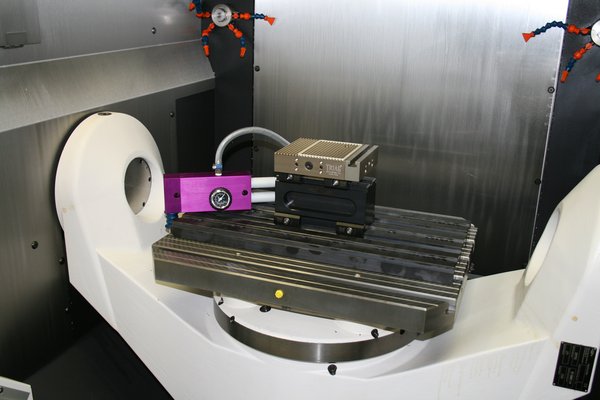

With powerCLAMP, we have combined the benefits of the classic machine vise with the modularity of an innovative workholding system. Over 200 standard modules allow for single or multiple workholding of workpieces in all sizes, shapes, and arrangements.

This approach provides a high level of flexibility and maximum clamping density. Your machine operator can clamp different parts at the same time, eliminating the cost intensive downtime in single-part and small batch size production, making your production as efficient as possible.